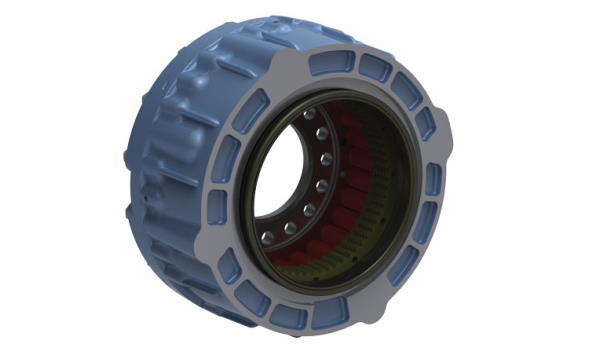

AxleTech Hydraulic Wet Disc Brakes

AxleTech Hydraulic Wet Disc Brakes

AxleTech wet disc brakes have been in the most severe and diverse vocational uses, including lift trucks, container handlers, reach stackers, both rigid and articulated haulers, log loaders, locomotive (mining and tunneling), compactors, rollers, underground mining and exploration, front-end loaders, agricultural spreaders, and asphalt pavers. Some of these wet disc brake applications are supported by unit mount brakes as well as integral to the current axle product range.

AxleTech Hydraulic Wet Dry Disc Brakes

Features & Benefits

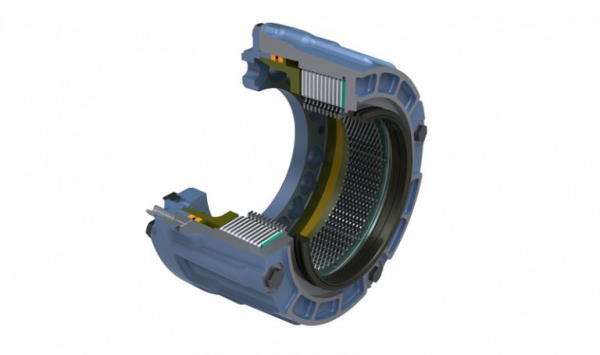

Technical Specifications

- Number of friction plates: 6 to 10

- Maximum rated torque: 120,000 lb in / 13,560 N m to 659,000 lb in / 78,535 N m

- Nominal actuation pressure: 1,500 psi / 103 bar to 350 psi / 24 bar

- Minimum wheel size: 20 in / 508 mm

AxleTech Hydraulic Wet Disc Brakes Available

- Hydraulic Wet Brakes W3H Series

- Hydraulic Wet Brakes W4H Series

- Hydraulic Wet Brakes W4M Series

- Hydraulic Wet Brakes WDM Series

Commonly Supported Equipment

- Agco

- Cargotec

- Caterpillar

- Foremost

- Hyster

- Hoist

- Kalamar

- Konecranes

- NMHG

- Nordco

- Pettibone

- Pierce Pacific

- PPM

- SISU

- Taylor

- Trex

- Valmet

- Wagner

- Yale

Heavy Duty Transaxle W4H Customer Supplied Rebuild Includes

| 1. Teardown & Cleaning • Detailed assembly/disassembly instructions are generated by cooperative effort with AxleTech Engineering • W4H brake assemblies are disassembled using appropriate equipment and fixturing • Visual and/or magnaflux inspections • Cleaning using media blast or chemical bath | 2. Machining & Rework • Rework processes/re-machining incorporated into the process if necessary • Bill of Material (BOM) verified and set up to track any re-machining or special processing • Any machining is planned and coordinated with AxleTech Engineering | 3. Assembly • Parts inspection • Use of all genuine service parts • Subassembly • Final assembly • W4H Brake Assemblies are leak tested per individual component to meet OEM specification |

Recent Projects

-

- September 5, 2022

- Uncategorized

We Want to Buy Your Surplus!

-

- September 1, 2022

- Uncategorized

AxleTech Custom Axles

-

- August 8, 2022

- Uncategorized

Surplus Axles in Stock